What is a Duct Smoke Detector and why are they required?

Consolidated Fire protection is a national company that performs the inspection, testing and maintenance for all fire protection needs and performs installations of Fire Alarm and Sprinkler Systems.

Best Practice for the Installation, Testing, Maintenance and Service / Repair of Duct Smoke Detectors.

Challenge:

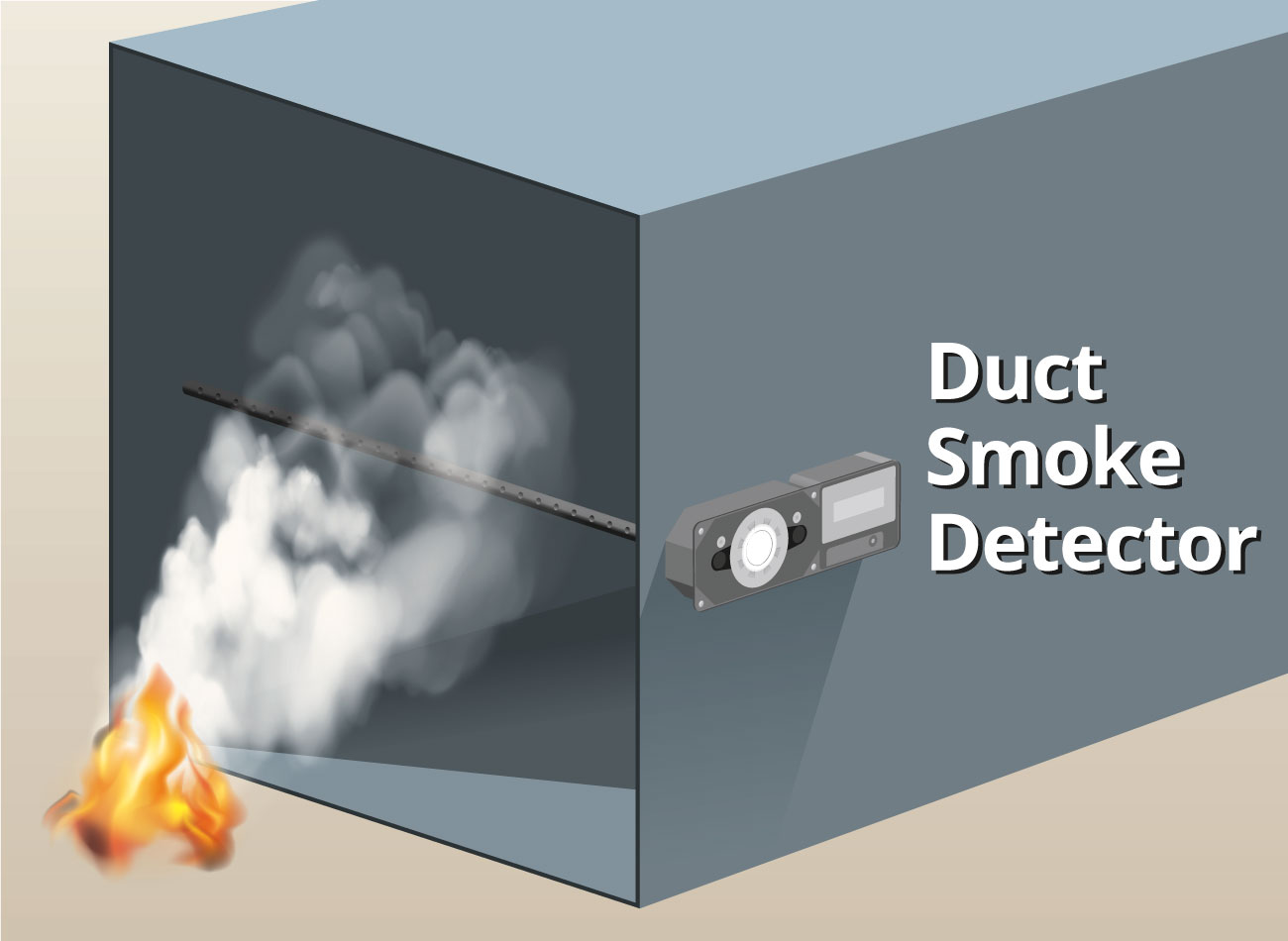

The installation of Duct Detectors can be a main cause of nuisance alarms and supervisory alerts. Duct Smoke Detectors are subject to the movement of air, dust and dirt within Heating Ventilation, Air Conditioning Systems (HVAC).

Duct Smoke Detectors that are factory installed in most Roof Top Units (RTU), the Duct Detector usually receives its power by the RTU, by using this method of power for the detector; the Fire Alarm Control Panel cannot reset the Duct Detector.

Duct Smoke Detectors can also be powered by 120 Voltage (VAC), the primary power for the Duct Detector is provided by an electrical circuit; by using this method of power for the detector, the Fire Alarm Control Panel cannot reset the Duct Detector.

Duct Smoke Detectors installed on the ducting of the ventilation system are being installed at an elevated height or above a hard lid or T-Bar ceiling; this installation practice creates issues with servicing and testing the device.

Due to the various ways of providing power to the detector, resetting the device after activation can be difficult for the end user and the building representative.

Inaccessible Duct Detectors is the most common issue that service and repair technicians have when performing testing or service of the device. NFPA 72 has requirements for remote LED and test station locations when the device is located above ceilings or the detector LED cannot be seen from the floor. NFPA 72 mentions the definition of accessible, as applied to the equipment. The Duct Smoke Detector is to be accessible to meet the definition, but is not always the case.

Why are Duct Smoke Detectors required :

NFPA 90A is specific to Air Conditioning and Heating Systems installation. The purpose of the NFPA 90A is to prevent the spread of smoke and fire through ductwork and ventilation systems for air conditioning and heating systems with high capacities.

The primary uses of the Duct Smoke Detector is to sample the air being moved through the ductwork for smoke and to stop the fan unit from running so smoke is not moved through the ducting.

In some applications, Duct Smoke Detectors can be used for the control of ventilation dampers.

Where are Duct Smoke Detectors required to be installed:

The International Mechanical Code requires a duct smoke detector in the return for units over 2,000 cfm and requires a detector in the supply duct for systems over 15,000 cfm.

There are other Codes and Standards that require the installation of Duct Detectors to be installed in the supply ducting of HVAC units that are over 2,000 CFM and in the return ducting or shaft if over 15,000 CFM.

When installing Duct Detectors it is advised to reach out to the local Authority Having Jurisdiction (AHJ) to obtain their requirement.

In air supply systems with a capacity greater than 2,000 CFM the Duct Detector shall be installed downstream of the air filters and upstream of any branch ducts.

In multi-story buildings, it states each story with a commonly shared return and having a capacity greater than 15,000 CFM’s. The smoke detection device should be installed before the connection to the common return and before any connection to any recirculation or fresh air inlet in the return air systems. The Code includes plenums where the plenum is used as the common return.

Duct Smoke Detection – NFPA 90A Code Requirements – There are exceptions to the two basic requirements:

Ventilation fan systems used to remove air from the inside of the building to the outside of the building. These fans are excluded from the above requirements and

Return air smoke detectors are not required when there is a protection of the space served by a system of area smoke detectors.

Best Practices implemented:

NFPA 72 National Fire Alarm and Signaling code has installation methods of Duct Smoke Detectors when connected to a building Fire Alarm Control Panel (FACP).

International Mechanical Code has installation requirements for Duct Smoke Detectors.

NFPA 90A has installation requirements for Duct Smoke Detectors.

In today’s world, most buildings have some sort of fire alarm system or dedicated supervisory system installed with-in the premise.

When Duct Detection is required, NFPA 72 (adopted edition) locally is widely accepted and followed.

Chapter 17, Initiating Devices and Annex materials is where one would find the required and recommended installation practices for Duct Detectors.

Conventional and Addressable Duct Detectors that are compatible with the control unit can be the easiest method of having the Duct Detector powered, supervised and reset from the control unit.

NFPA codes and standards have requirements for providing signage of the power source for the device; the required signage shall be installed next to the control unit, noted on inspection paperwork or in the O&M manual.

NFPA 72 2013, 2016 and the 2019 editions have resetting requirements listed in Chapter 23 for protected premises alarm and signaling chapter. With-n this requirement, if the power for a duct detector is not provided by protected premises fire alarm control panel, a listed indicator with an internal reset switch shall be provided in an accessible location.

Results of Best Practice:

Accessibility of Duct Detectors is done by diligence during the installation, record of location in project and acceptance documents, and notes on inspection reports during the Inspection, Testing and Maintenance of the device.

These items mentioned above, if met, will help Technicians access the device when needed and assist the Technician and End User to be able to reset the device and the Fire Alarm Control Panel (FACP).

Verification of Efficiency and/or Savings Captured:

Locations of Duct Detectors are documented in the installation and acceptance documentation, and is kept at the protected premise in the document box, by having this information on site and in records, the testing and maintenance of Duct Detectors is completed at the time of service with no return trips needed for lifts and access.

Resetting the Duct Detector from the Fire Alarm Control Panel (FACP) will reduce service call costs to the building owner.